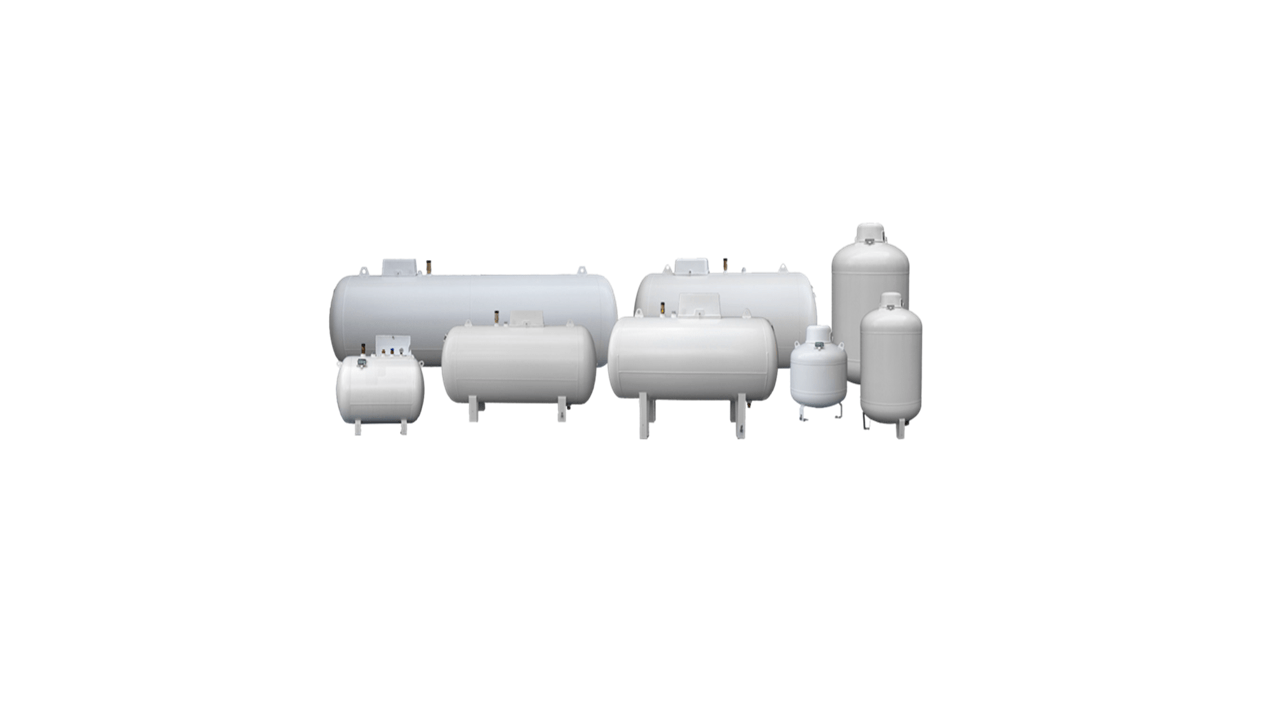

An LPG storage facility is essentially made up of one or more tanks of appropriate capacity, equipped with operational, control and safety equipment and is designed and manufactured in compliance with the requirements of the European Directives and related harmonized standards for pressure equipment (PED 2014/68/EU – ATEX 94/9/EC).

Materials: P355NH

Operating pressure: 17.65 bar

Design temperature: -20°C / +50°C

Capacity :

Horizontal axis: 650 – 990 – 1000 – 1750 – 2750 – 3750 – 5000 – 7150 – 10000 – 12500

Vertical Axis: 295 – 500 – 700 – 1000 – 1650 – 2250

Safety and Service Equipment and Accessories

An identification plate is placed on the tank showing all the characteristic data of the tank and the CE 100 mark identifying the INAIL notified body (CE 0100) that carried out the PED conformity verification.

The data on the nameplate or the identification booklet (which must be associated with the tank) are:

Factory Number

Name of the Manufacturer

Year of Construction

Design Pressure

Design Temperature

Each tank is supplied already assembled with safety and service accessories and equipment.

Corrosion Protection

A protective coating treatment is applied on all tanks to prevent the initiation of corrosive phenomena.

Prior to this, each tank undergoes a white metal blasting cycle of the external surface in accordance with international standards (Svens.stand. SA 2.5).

Above Ground tanks

Following external sandblasting (grade SA 2.5), the anti-corrosion coating is carried out by means of a painting cycle involving the application of one coat of two-component epoxy anti-corrosion protective primer and one/two coats of white RAL 9012 two-component epoxy finish. The minimum overall thickness at any point on the exterior surface cannot be less than 90 µm to ensure adequate corrosion and UV protection.